Our Plastic Materials

For the production of pipeline components, Praher uses mainly following thermoplastics:

Advantages in the use of plastics

Right choice of material

1. Chemical resistance

The chemical resistance list gives an informative overview of our thermoplastics and elastomers. We distinguish three types of resistance:

Resistant materials: The material is unaffected.

Conditionally resistant materials: The medium can attack the material or causes swelling, service life is shortened. Reduced operating time and operating pressure.

Non resistant materials: The material is greatly impaired.

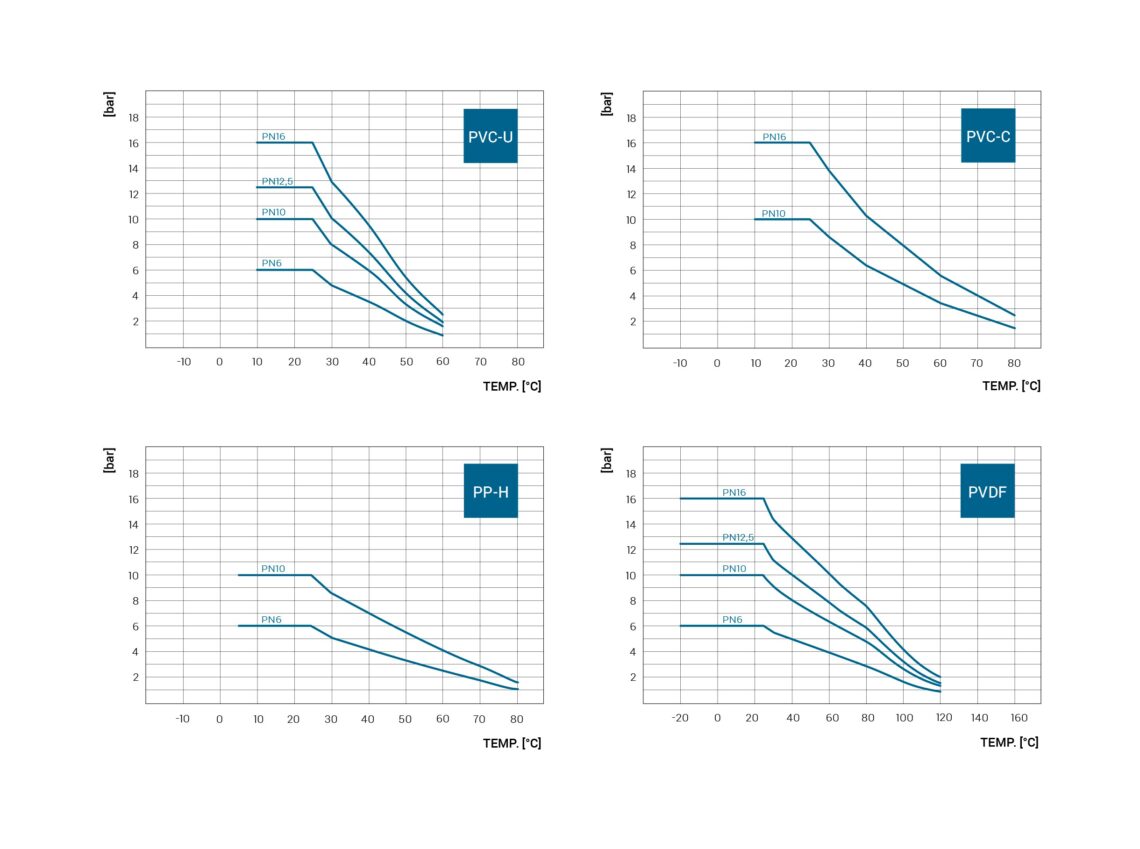

2. Pressure-temperature-ratio

The pressure rating (PN marking) of an industrial part made of thermoplastic is determined for water as medium at a temperature of 20°C and a constant pressure. The pressure-temperature load capacity is of great importance for an optimal operation for a long service life of a thermoplastic industrial piping system. This results in a temperature reduction factor:

3. Safety or Design Factor

It should be also taken into consideration that the transported medium and the environment around the piping system respectively has an influence on the pressure resistance. In conclusion, the pressure reducing factors (as safety or design factors) can be determined by means of the diagrams above with reference to changing temperature conditions. Finally, the Safety or Design factor has to take into consideration all characteristics of a specific pipe line, like for example:

• pressure peaks – water hammer

• chemical resistance

• temperature fluctuation

• operating states (cavitation, abrasion, …)